Determining the Size of Your Investment Casting Project

September 17, 2021

How it’s Made: Casting Molds

November 15, 2021Benefits of Having an Investment Casting Foundry in Mexico

In any business, quality and affordability are two things that everyone is looking for. This is especially true in precision casting, where poor quality can lead to a very expensive process, even more so if the casting company has high initial costs.

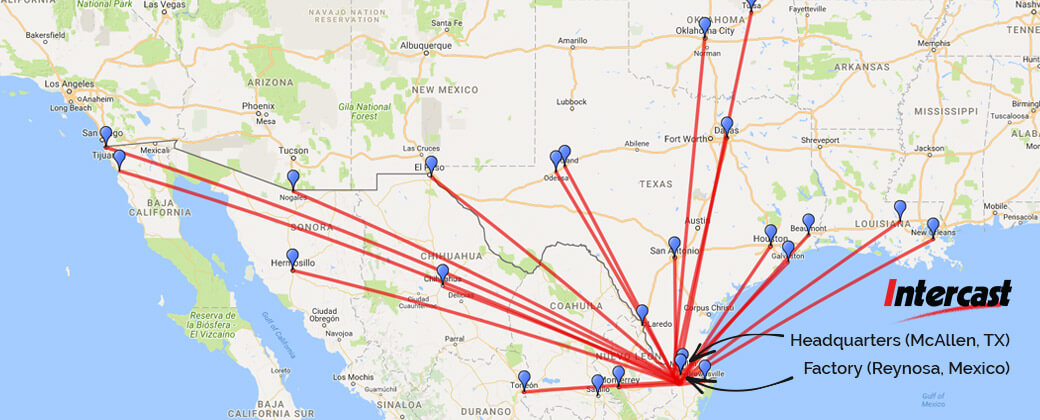

At Intercast, one of our greatest advantages is our foundry, which is located approximately 10 miles south of the U.S. border with Mexico. This allows us to offer our customers better prices, without sacrificing in the areas of quality or customer service. Through the years, we have found many benefits of having an investment casting foundry in Mexico.

World-Class Pricing

Our foundry operates as a maquiladora, which gives us many distinct advantages. One way that we lower costs is through the advantageous tax treatment that maquiladoras receive. This includes the importing of materials and equipment on a duty-free basis, giving us lower operating costs, which we are then able to pass onto our customers.

Operating our investment casting foundry in Mexico also allows us to take advantage of lower labor costs that are naturally incurred in Mexico. While the wages may be lower than a typical United States factory worker, the truth is that these wages are excellent compared to other industries in Mexico. Not only does this save on costs, but these are also in demand jobs that feature lower than we often see in U.S. factory jobs. This cuts costs not only in an ongoing basis, but also due to lower job searches and training.

At Intercast, we own the manufacturing process from start to finish, which allows us to truly focus all of our attention on providing the best precision components possible, while also keeping our costs as low as we can. Everything we do is aimed at fulfilling these two goals for every customer.

Skilled, Quality Workforce

As mentioned earlier, the low amount of turnover means that our workforce is highly skilled, carrying out even the most complex casts with superior ability and technical skill. At Intercast, we have demonstrated this quality with over 60+ years of experience in the investment casting industry, building our reputation based on this quality.

Our foundry is a world-class facility that is secure and stable, located in a modern industrial park with safety and security that is equal to the United States. Our extensive manufacturing resources give us almost unlimited design flexibility for your cast. Our workforce is educated, experienced, and bi-lingual for easier communication both in the United States and Mexico.

This skill also allows us to use any alloy you want, no matter the configuration. We understand that different metals work best in a project depending on the specifications and industry, and we use our leadership team’s 125+ years of experience to determine what will work best for your job. We know you trust us to be the experts when it comes to crafting your cast, and we take that responsibility very seriously in everything we do.

Reduced Lead Times

Since our foundry is located so close to the border, we experienced reduced lead times to our competitors, offering many strategic location advantages. We have the capacity and capability to produce low, medium, or higher volume production runs on a consistent basis, reducing the time it takes for you to receive your cast.

Our location in Mexico also allows for low shipping costs and quick delivery, which helps make us a more affordable option. Our lean manufacturing capabilities mean that it can take just hours for a cast to be delivered from our foundry in Mexico to the United States, cutting down on long trips from across the country or even across the world. This saves money both on the transportation of casts as well as any warehouse costs.

We have experienced and established logistics and customs services, helping keep everything cost effective even as our casts move from our foundry in Mexico to our customers in the United States. With our extensive experience, we do not experience any hiccups crossing the border, which helps keep our lead times low for each job.

We understand that when you need an investment cast done, it is advantageous to receive it as quickly as possible. Our reduced lead times help save you both time and money by delivering a quality cast to you more quickly than our competitors.

Outstanding Customer Service and Collaboration

Our foundry is located in the central time zone, allowing for real-time collaboration and adaptability throughout any project. We take pride in our outstanding customer service, working with you to determine the best cast for your job, and then having the capacity and skill to create that cast in our foundry.

We work with you to create custom supply chain options, with everything from Kanbans to managed inventory agreements. This reduced the total cost of ownership for you, while delivering the most possible value even through inventory fluctuations. Our rapid prototyping allows us to provide you with sample castings more quickly and cheaper than our clients. By using QuickCast or SLA material technology, we created a 3D printed pattern which will be processed and casted. This cuts costs and gives you more confidence in the work we are doing for you.

You can contact us anytime through our website, or by giving us a call at 956.688.6406. Whether you want to request a quote or work through a problem, we are fully committed to helping build efficient, cost effective supply chain programs. We go the extra mile to partner with our clients to find the best solutions for them, both now and in the future.

At Intercast, having our foundry located in Mexico is at the heart of how we stay ahead of our competition. We have the best of both world with lower production costs which make us very affordable for our clients, while maintaining the highest levels of quality that you need and expect. Contact us today to get started, and let us prove our quality to you.