FDA Compliant Investment Casting For Food and Beverage Suppliers

February 22, 2021

Deciding between Stainless Steel Casting and Cast Iron

April 23, 2021What You Need to Know About Aerospace Investment Castings

The aerospace industry is one that requires absolute precision with every casting done. With the high stakes and intricate parts involved, aerospace castings demand the quality work and attention to detail of an experienced and skilled investment casting company.

At Intercast, our leadership team has more than 125 years of combined experience in investment castings, giving us the expertise to meet the demands or aerospace investment casting. With our philosophy of “continuous improvement,” we understand the demands that aerospace investment casting, and our dedicated to providing quality casts every time.

Control Over Every Aspect

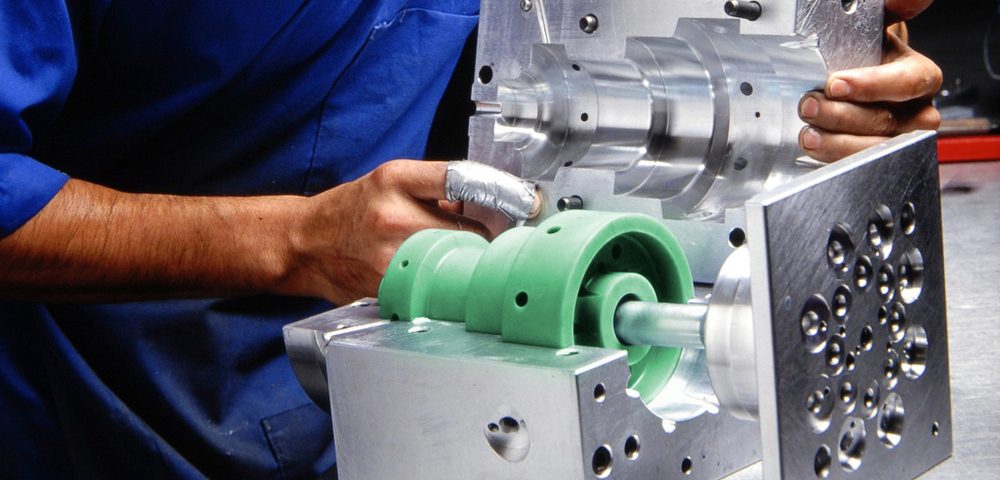

One important criteria for any aerospace casting supplier is the ability to have 100% visual inspection and control over every aspect of the casting process, from wax all the way to final packaging. With our foundry which operates as a maquiladora, we have total control over the entire process, which gives us cost reductions, design flexibility, and reduced lead times compared to our competitors. We have on-site inspection teams to oversee the entire process, helping give our customers added assurance the quality of the final product.

Depending on the plane and item, aerospace investment castings can be made with any of a number of alloys, which provide different benefits. Through our process, we offer an infinite choice of alloys, with the flexibility to take on any configuration. Do you need your parts produced as cast or finished machined? Common aerospace casting alloys include stainless steel, low-carbon steel, 17-4PH, and even specialty alloys such as silicone bronze or beryllium copper. We work with you to find the best alloy for your job, focusing on high strength/low weight ratios that are resistant to temperature and corrosion, allowing them to hold up no matter the situation.

Aerospace castings typically are complex parts, featuring intricate detail along with the need for unmatched durability. At Intercast, we work with your specifications, using our expertise to help throughout the process. Our reputation has been built on providing quality castings no matter the level of detail or intricacy involved, and we have demonstrated for over 60 years that we stand behind the quality of our work.

Knowing for its near net shape capabilities, investment casting allows you to design a component with various features which are utilized as a cast. We fully understand the investment casting process, which allows us to create strategic advantages for our clients, helping design parts that match exactly what you need and are looking for.

Rapid Prototyping and Design Flexibility

There are many different applications and parts that we produce for the aerospace and aviation industries, all of which play distinct roles and have distinct specifications. These include flight critical and safety components, landing and braking components, and hydraulic fluid system components, all of which are vital to the safety of the aircraft.

We also produce some of the less noticed parts that help make any ride a safe and enjoyable experience for everyone, including interior components, exterior and interior sensors, cargo systems, bearing cages, and motion control and actuation systems. Each component requires different parts, different designs, and different alloys, making the importance of experience a vital one in the production of aerospace castings. We understand the advantages and disadvantages of different allows, helping you find the right fit for every component in your job.

OEM, Tier One and Two manufacturers all trust Intercast to provide high quality parts that fit within very tight tolerances and specifications, all within specific deadlines. Our rapid prototyping 3D printing allows us to provide sample casting faster and cheaper than other competitors in the market, allowing our clients to more easily strategize and become comfortable with the product. Not only does this help reduce costs, but it also helps cut down on time so you be working on projects rather than waiting for parts.

In any industry, reducing costs while still getting high quality parts is of the utmost importance. This is why our foundry is such an advantage, as it allows us to provide world-class pricing while delivering high quality, flexibility, and outstanding customer service. With an experienced and bi-lingual work force, we have real-time collaboration with our foundry, allowing us to maximize designs and deliver the product you need. We are fully committed to offering custom options within our supply chain that help reduce the total cost of ownership, including Kanbans or managed inventory agreements. We are dedicated to offering the best value castings in the industry, without compromising on quality and dependability.

With the ability to produce low, medium, or high volume production runs, our reduced lead times help you get what you need, when you need it. We understand that the aerospace industry is more competitive than ever, which is why reduced lead times and a steady flow of products is important for business in the aviation industry to compete.

The Intercast Difference

Even more than other industries, the stakes are high in the aerospace industry, and any mistake could mean big consequences. Part of our high reputation is built on our philosophy of continuous improvement – that no matter how many quality parts we produce, we approach each day looking for how we can get better, and how we can offer even greater value for our clients while maintaining our strict quality standards. Whether we’re working on creating an initial design for a project, monitoring the process, or verifying that everything is going as it should, our quality control department ensures that the highest possible standards are met in everything that we do.

With our experience as an aerospace casting supplier, we work to develop relationships with our clients that are mutually beneficial, as we saw all of our clients as partners for the long haul. We believe that the best partnerships happen when both sides work together out of respect to come up with great solutions and ideas. If you are looking for quality investment casts in the aerospace industry, contact us today to request a free quote.